Understanding Concrete Cube Testing in the UK: A Guide to BS EN 12390-3 Standards

Concrete cube testing is an essential process in the UK construction industry, ensuring the durability and safety of structures through stringent quality standards. In accordance with BS EN 12390-3, this testing method plays a crucial role in determining the compressive strength of concrete, which is vital for assessing its suitability for various applications. In this blog, we'll delve into the significance of concrete cube testing, the procedures outlined in BS EN 12390-3, and its importance in maintaining construction quality standards in the UK.

Importance of Concrete Cube Testing:

Concrete is a fundamental building material used in the construction of bridges, buildings, roads, and other infrastructure projects. Its compressive strength, or the ability to withstand crushing forces, is a critical factor in determining its quality and durability. Concrete cube testing provides a reliable method for assessing this strength, ensuring that structures meet the necessary safety standards and regulatory requirements.

BS EN 12390-2 & BS EN 12390-3 Standards:

BS EN 12390-2 is a British Standard that specifies the procedures for making and curing concrete specimens for strength tests. It outlines the requirements for preparing, casting, and curing. BS EN 12390-3 is a British Standard that specifies the testing of concrete cubes to assess their compressive strength accurately. Adhering to these standards is essential for obtaining reliable and consistent test results, thereby ensuring the quality and integrity of construction projects.

Key Procedures in BS EN 12390-2 and BS EN 12390-3:

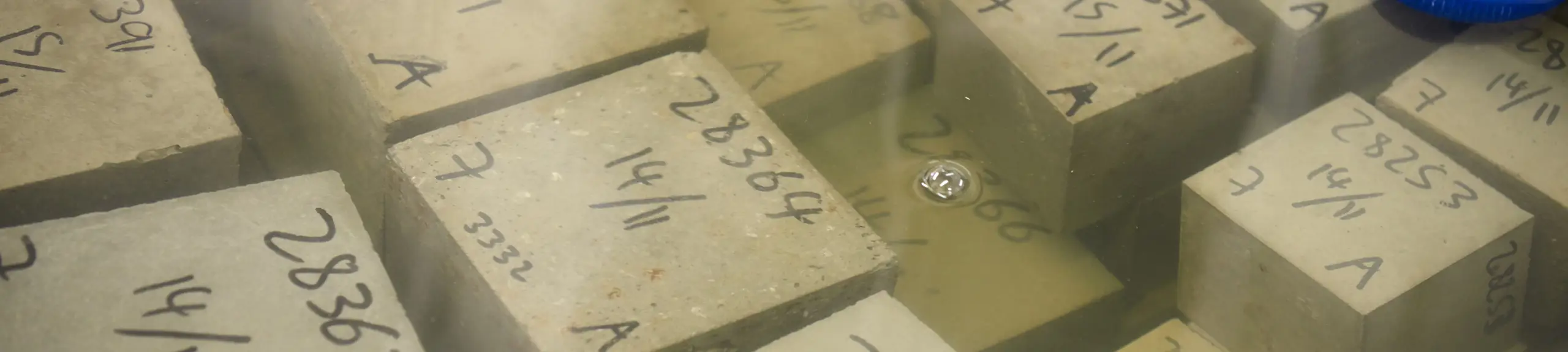

Specimen Preparation: The standard specifies the dimensions of concrete cubes to be prepared for testing, typically measuring either 100mm x 100mm x 100mm or 150mm x 150mm x 150mm. These cubes are cast from fresh concrete samples obtained during production.

Curing Conditions: Proper curing is crucial for the development of concrete strength. BS EN 12390-2 prescribes specific curing conditions, including temperature and humidity requirements, to ensure optimal specimen development.

Testing Procedures: After the specified curing period, concrete cubes undergo compression testing using a hydraulic press. The maximum load at which the cube fails is recorded, and the compressive strength is calculated based on the cross-sectional area of the cube.

Reporting Results: Test results are reported in megapascals (MPa) or newtons per square millimeter (N/mm²), indicating the compressive strength of the concrete specimen. These results are essential for evaluating the quality of the concrete mix and its suitability for the intended application.

Importance of Compliance: Adhering to British Standards is critical for ensuring the accuracy and reliability of concrete cube testing results. Compliance with these standards demonstrates a commitment to quality assurance and helps uphold the safety and performance of construction projects in the UK.

Testing Facilities

In addition to following procedures such as BS EN 12390-2 & 3, the choice of testing facility can significantly impact the quality of results. This is where the accreditation by the United Kingdom Accreditation Service (UKAS) plays a pivotal role. Let’s explore why projects should opt for a UKAS-accredited business for the making and testing of concrete cubes and how it contributes to maintaining the highest standards of quality assurance.

Importance of UKAS Accreditation in Concrete Cube Testing:

Quality Assurance: UKAS accreditation ensures that the testing facility operates according to internationally recognised standards, including BS EN 12390-2 & 3. This provides confidence in the accuracy and reliability of the test results, crucial for making informed decisions in construction projects.

Technical Competence: Accredited businesses have demonstrated their technical competence in performing concrete cube testing. This includes employing trained personnel, utilising calibrated equipment, and following standardised procedures to ensure consistency and accuracy in test results.

Impartiality and Independence: UKAS accreditation signifies the impartiality and independence of the testing facility. Accredited businesses operate free from conflicts of interest and external influences, ensuring that test results are unbiased and credible.

Benefits for Projects:

Compliance with Regulatory Requirements: Many regulatory authorities and industry bodies require concrete cube testing to be conducted by accredited laboratories. Choosing a UKAS-accredited business ensures compliance with these requirements, avoiding potential delays and issues during project approvals.

Risk Mitigation: Accurate and reliable test results from UKAS-accredited facilities reduce the risk of structural failures and associated liabilities. This helps in mitigating risks associated with poor quality construction, ensuring the long-term safety and performance of structures.

Enhanced Reputation: Collaborating with UKAS-accredited businesses reflects a commitment to quality and excellence in construction projects. This enhances the reputation of project stakeholders, demonstrating their dedication to delivering high-quality and compliant structures.

In conclusion, concrete cube testing, in accordance with BS EN 12390-2 & 3 standards, while incorporating testing conducted by UKAS-accredited businesses, is a vital aspect of quality control in the construction industry.

Adhering to these standards is essential for maintaining construction quality standards and upholding the integrity of infrastructure projects.

To find out about the range of concrete testing services available from CTS visit.